Arris Builders – Settled Tilt Up – Diamond Bar, CA

Project Background Information:

The Arris Project Tilt Up is located on one of the many slopes in Diamond Bar that over look the 60 Freeway. Being on a slope and not having an adequate foundation system is place had caused this building to have settled over 8” from it’s time of initial construction. The building is a 2 story tilt up that sits upon a combination foundation consisting of a shallow 36” footing as well as 46 interior and exterior pad footings.

A local investment group had recently purchased the building and has a complete building renovation to ensue after the building’s foundation has been raised and leveled.

Project Design Phase:

The initial design concept for the project consisted of utilizing a combination of MicroPiles and grade beams to be installed on the structure. There were a total of 59 MicroPiles designed to go around the perimeter of the building. Fill materials were found to be in the range of depths of 30’ – 50’.

Dalinghaus Solution:

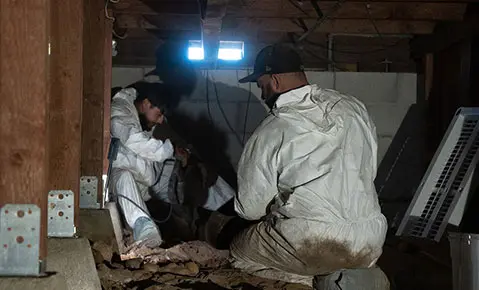

During Dalinghaus Construction’s initial plan review and site visit we informed the client that the project may be able to yield better end and time frame results utilizing another deep pile product. The initial project data was provided to our engineering staff for review. They came back with a design that utilized a combination of 87 push piers, 12 helical tiebacks, and 10,000 pounds of polyurethane grout injection.

The push piers were installed on both the exterior footing and the interior pad footings. The piers were installed to depths ranging from 30’ to 50’ and an installation value exceeding 28,000 lbs.

Tiebacks were installed on the perimeter footing in calculated locations to allow the building to resist the lateral movement that it was also experiencing. The tiebacks were installed from depths ranging from 26’ to 50’ with an installation torque value exceeding 4,100 ft/lbs.

Polyurethane grout was injected into the soil and under the slab to assist in the lifting of the building. The polyurethane was also able to consolidate the loose materials under the slab to provide support to the previously unsupported building slab.

Read more – Top 3 Signs Your Foundation May Be Settling

Project Team

Structural Engineer: Helfrich and Associates

Geotechnical Engineer: Robles Engineering, Inc

General Contractor: Arris Builders

Tieback/Pile Installer: Dalinghaus Construction, Inc

Products Installed

- 87 ECP PPB 300 Model Push Piers

- 12 ECP TAH-150 8”/10” Helical Tiebacks

- 10,000 lbs of NCFI 010